Products

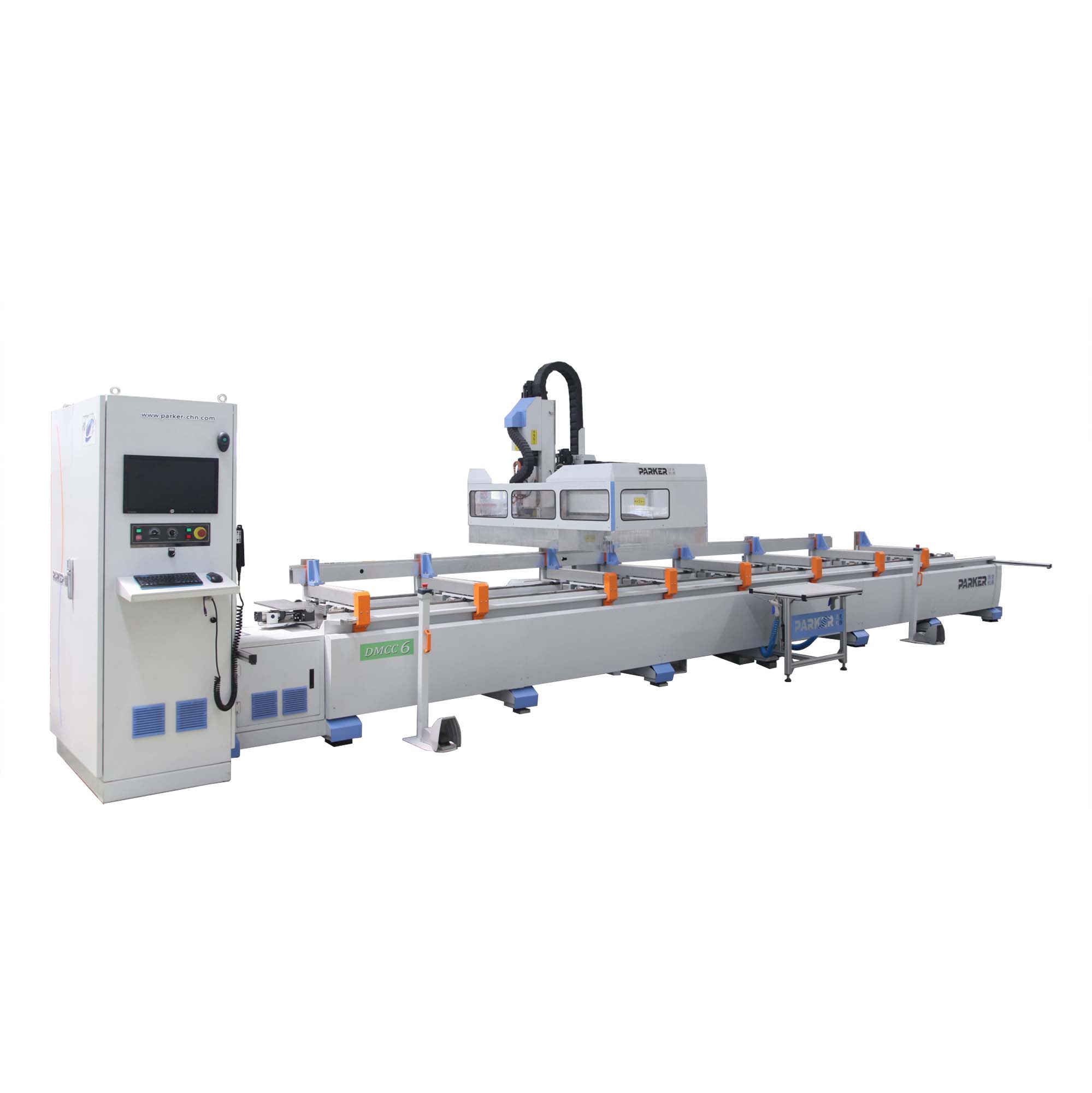

4 Axis CNC Machining Center

The machine is suitable for processing installation holes, water slot, shaped holes, and end milling and making screw on curtain walls and aluminum windows and doors

Feature:

◆ The machine is suitable for processing installation holes, water slot, shaped holes, and end milling and making screw on curtain walls and aluminum windows and doors.

◆ It adopts high-speed electric principal axis, which is imported from Italy. It is extremely efficient and can swing in±90°

◆ It adopts high-quality computer control system which is used in industry area specially, with good user interface, graphical programming and processing tracking interface, truly realize what you see and what you get.

◆ It adopts high-quality servo motor, ball screw, linear guide pair and bearings and so on to ensure the machine runs with high precision.

◆ Equipped Six cutters positions, the cutter can change quickly and automatically .

◆ The semi-closed guard improved security greatly.

◆ Clamping device position can be optimized and put to right position automatically and freely.

TECHNICAL DATA.

STROKE

(Stroke for X axis) 7600mm

(Stroke for Y axis) 870mm

(Stroke for Z axis) 610mm

SPINDLE

(Spindle Speed) 18000

TOOLS

(Capacity Of Tools Magazine) 6

(Tool Change Time) 2.8s

MOVING SPEED

(X Axis Moving Speed) 0~90m/min

(Y Axis Moving Speed) 0~80m/min

(Z Axis Moving Speed) 0~70m/min

(X/Y/Z Feeding Speed) 0~2000mm/min

POWER OF MOTOR

(Spindle Driven Motor) 5.5kw

(X/Y/Z/A Driven Motor) 1.8kw、0.85kw、0.85kw、0.75kw

LUBRICATING SYSTEM

(Lubricating System) Bijur

(Cooling System) SAGELY

(Position Precision Of X Axis) ±0.05mm

(Position Precision Of Y /Z Axis) ±0.02mm

(Repeating Position) ±0.02mm

(Power Supply) 380V/50Hz

(Power) 12kw

(Air Pressure) 0.5-0.8Mpa

(Weight) 4.7t

(Area) 10100×2300×2600mm

MAIN COMPONENT CONFIGURATION