Products

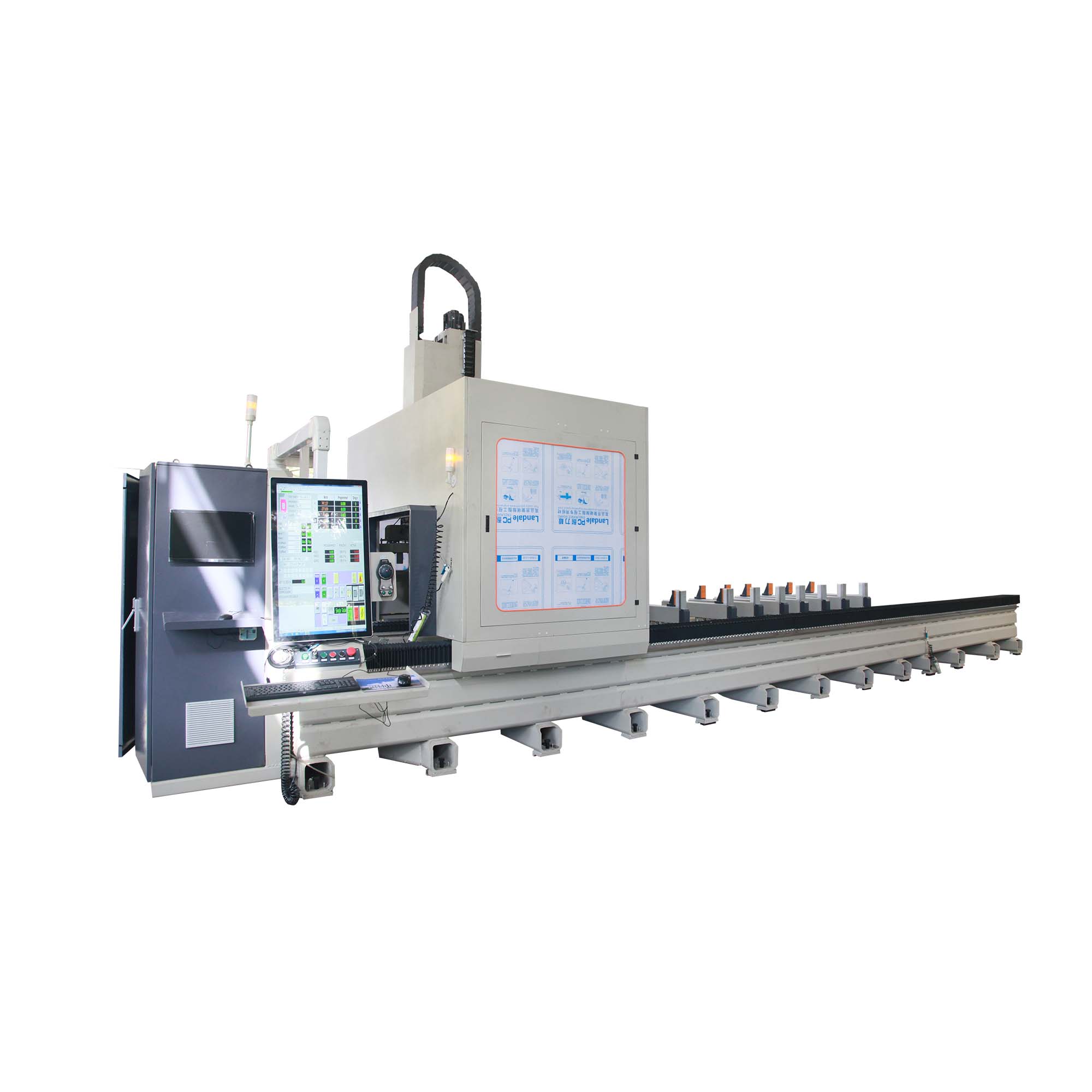

Five axis Gantry CNC machining Center

Features:

●Using gantry frame structure, running more smoothly, improve the rigidity of the machine tool.

● Suitable for all kinds of aluminum, copper, PVC, industrial profiles and other complex parts processing. Can achieve a workpiece clamping automatically completed milling, drilling, tapping and other multi-process processing.

● Imported well-known brands, easy to operate high-end CNC control system from Italy.

● The use of high-quality imported servo motor, ball screw, linear guide and other bearings and other institutions to ensure that the equipment has a high processing accuracy. High stability, reliability. The feed movement is pre-stretched to ensure the stability of the machining accuracy.

● The machine adopts the imported five-axis milling head to finish the processing at any angle on the other side of the bottom surface. Optional vertical disc 8-bit magazine.

● The use of quantitative timing of the central centralized automatic feed lubrication to ensure the stability of the machine accuracy.

● Use pneumatic clamping table to improve loading and unloading speed. Optional T-type table.

● The use of imported Renishaw interferometer detection, compensation for the accuracy of the machine.

● Use safety protection to ensure safety.

TECHNICAL DATA.

STROKE

Stroke for X axis 7000

Stroke for Y axis 1000mm

Stroke for Z axis 550mm

SPINDLE

Spindle Speed 24000r/min

Spindle Taper HSK-63F

TOOLS

Capacity Of Tools Magazine) 8

MOVING SPEED

X Axis Moving Speed 0~60m/min

Y Axis Moving Speed 0~30m/min

Z Axis Moving Speed 0~30m/min

LUBRICATING SYSTEM

PRECISION

Position Precision Of X Axis ±0.05 mm

Position Precision Of Y /Z Axis ±0.02 mm

Repeating Position ±0.01 mm

SIXE OF MACHINE

Power Supply AC 380V 50Hz

Air Pressure 0.5MPa – 0.8MPa

Weight 24000kg

Area 15500×3000mm

MAIN COMPONENT CONFIGURATION