Products

1.Schneider Electric System in France: Stable performance accessories for servo motors and PLC can be purchased anywhere in the world.

2.32 inch HD industrial touch screen: Can link MES system, server, Cloud server, and can be connected remotely.

3.Operating software: self-developed, with strong flexibility, high adaptation rate, and ability to interface with optimization software, reducing worker operation errors, and eliminating the need for highly skilled operators, reducing labor costs.

4.The mechanical feeding arm clamping mechanism is rotatable and has diverse clamping methods, which can handle various profiles.

5.Max. loading 6 profiles in feeding area.

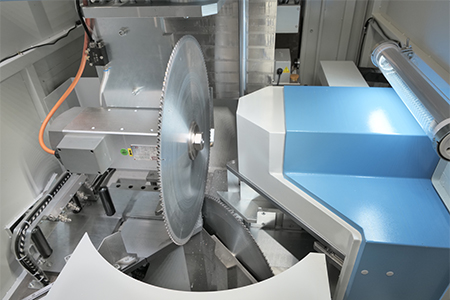

6.The cutting angle can be changed ±45 ° and 90 ° . The Z-axis is server motor controlled motion with high cutting efficiency.

7.Automatic calculate the height of the profile before the angle cutting, ensuring the accuracy of the cutting angle.

8.The manipulator is adopted screw and server motor droved, with controllable travel and fast output speed and high efficiency.

9.Equipped with printer automatic printing and fast pasting function, it can quickly label profiles and provide a perfect solution for subsequent processes.

10.Adopted chip conveyor is convenient for collecting Aluminum scraps and chips.

11.The feeding and output sections are fully servo motor controlled, ensuring precise feeding. The feeding speed can reach 120 meter per min.

12.The average cutting circle time is about 10-13 seconds per piec

|

Power Supply |

AC 380V 50Hz TN-C |

|

Total Power |

14kw |

|

Gas Consumption |

200L/min |

|

Air Pressure |

0.5MPa – 0.8MPa |

|

Weight |

3.6t |

|

Overall Dimensions (L × W × H) |

12800mm×4000mm(with waste treatment device)×2450mm(L x W x H) |

|

Blade Specification |

Φ550 |

|

Saw Blade Spindle Motor Power & RPM |

3.0kw×2 /2800 RPM |

|

Cutting Angle |

±45° & 90° |

|

45° Cutting |

170x160mm(W×H) |

|

90° Cutting |

170x160mm(W×H) |

|

Max. & Min. Cutting Length |

200mm(related to the width of the profile)~6400mm |

|

Cutting Length Accuracy |

±0.15mm |

|

Profile Maximum Loading Length |

6400mm |

|

Max. Loading Profiles In The Loading Area |

6 PCS |

|

Cut Piece At One Time |

1 PCS |

|

Feeding Manipulator Stroke |

7500mm |

|

Moving Speed Of Feeder |

120m/min |

|

Feeder Stroke |

850mm |

|

Moving Speed Of Feeder |

60m/min |

|

Saw Blade Vertical Moving Speed |

20m/min |