Products

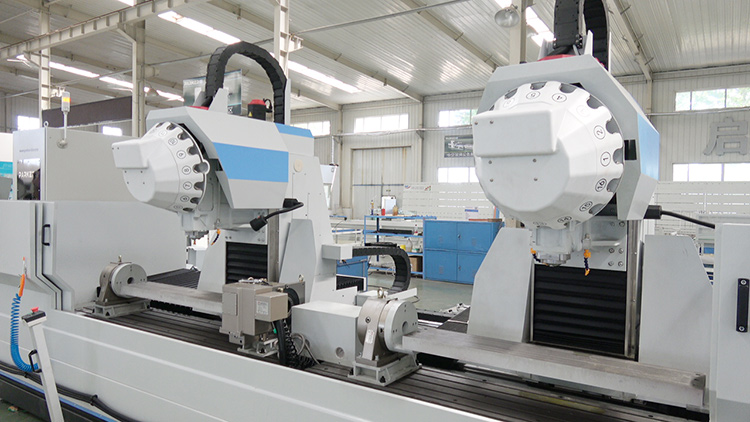

Aluminium profile double head high spend 3-axis CNC machining center

FUNCTION

1, Integrated machine structure of grade Q235A steel, with annealing and aging treatment, which ensures complete machine of high stability.

2,Integrated design of electrical cabinet and machine body makes transportation , installation ,operation much easier,and the stability more higher.

3, LH/RH - the left and right clamps , including corresponding fixtures are interchangeable, clamps in different positions are also interchangeable.

4, Equipped with chain type chip removal system, easy for cleaning, and adopts oil-water separator, which can separate lubrication oil and water automatically.

5, It’s high efficient with double heads and double –position processing.

6, X, Y, Z axis max. positioning speeds can reach up to 56M, 30M, 30M / min.

7,Equipped with Taiwan OBRAUN CNC Turning Table configured as the fourth axis. The positioning precision is within 20 arc seconds and the maximum limit approach 0 degree space, which greatly improved the processing precision and can achieve 360 degrees processing at one time clamping.

8, Clamps are equipped with switches, the pressure gauge and regulator make clamps adjustable and visible, human-friendly design, easy to operate, prevent the loosening of profiles to the maximum extent .

9, Full protection for cables, guide rails, racks and screws, effectively prevent fragments inside during processing, and greatly improve lifetime of these spare parts.

10, Equipped with automatic lubrication system for rails, which is convenient for maintenance.

11, Equipped with recycle water cooling system, which can effectively protect and improve lifetime of milling drilling tools; equipped with oil-water separator, which can separate lubrication oil and improve lifetime of lubrication fluid.

12, Spindle adopts GELLS brand ( Taiwan ), maximum speed up to 15000Rpm; Owing to the max. Working speed for machine is 12000RPM, spindle is used by reducing speed, which makes machine performance and working life much higher than similar products. .

13, Tool magazine adopts KUJI brand ( Taiwan ), equipped with 16 tools, neighboring tool change speed is 2.5 seconds .

14, Rigid tapping function makes the process faster and precise .

15, Servo spindle motor can output max. 23.9Nm during low-speed, speed up to 12000rpm, fully suitable for heavy steel, copper and aluminum profiles.

16, Base for rotary turret is widened and thickened, which improved the stability of complete machine and reduced self vibration to the maximum extent during processing.

17, Equipped with specific fixtures for profiles, greatly improve the stability of profile during processing, and reduce the resonance phenomenon effectively.

18, It is equipped with original imported Japanese FANUC 0I MF CNC system with double heads and double channel system, much easier, stable and practical; And it is equipped with tools management system lonely, which makes it convenient for tool life management.

19, It is equipped with oil-water separator, by which oil and water can be separated automatically.

Equipped with automatic water cleaning gun to clean clamps. It adopts "fixed point and direction” flushing design. It’s much convenient for cleaning clamps by installing a single nozzle or multi-nozzles at higher side of each clamping fixture. After the robot removed profiles, high-pressure water can be sprayed automatically to clean fixtures for 2-3 seconds, the arm change to the new material for the cycle of processing. (controlled by M code ).

21, The energy-saving air gun device can also clean clamps by using of pneumatic pressure .

22,Equipped with automatic protective safety door and adopted pneumatic control system. Separately reserved interface for the optional function of the mechanical arm installation,

23, The seller reserves manipulator interface so as to cooperate with the buyer to increase the mechanical arm.

TECHNICAL DATA.

STROKE

(Stroke for X axis) 总行程3500mm 单个行程1200mm

(Stroke for Y axis) 400mm

(Stroke for Z axis) 400mm

SPINDLE

(Spindle Speed) 12000 RPM

TOOLS

(Tool Change Time) 3.0s

MOVING SPEED

(X Axis Moving Speed) 52m/min

(Y Axis Moving Speed) 30m/min

(Z Axis Moving Speed) 30m/min

(X/Y/Z Feeding Speed) 0~2000mm/min

POWER OF MOTOR

(Spindle Driven Motor) 5.5KW

(X/Y/Z Driven Motor) 1.8KW、 1.8KW 、1.8KW

LUBRICATING SYSTEM

(Lubricating System) Bijur

(Cooling System) SAGELY

PRECISION

(Position Precision Of X Axis) ±0.05mm

(Position Precision Of Y /Z Axis) ±0.02 mm

(Repeating Position) ±0.02 mm

SIXE OF MACHINE

(Power Supply) AC 380V 50Hz

(Power) 40KW

(Air Pressure) 0.5MPa – 0.8MPa

(Weight) 11.5t

(Area) 6000*3100*2800mm

MAIN COMPONENT CONFIGURATION

(Operation System) FANUC

(Serve Motor) FANUC

(Spindle Motor) FANUC

(Spindle) CELL

(Guide Rails) THK

(Bearings) NSK

(Ball Screw) TBI

(Electrical Parts) Schneider

(Pneumatic Components) AIRTAC、SMC

(Reducer)ATG

(Water Pump)