Products

Main Feature

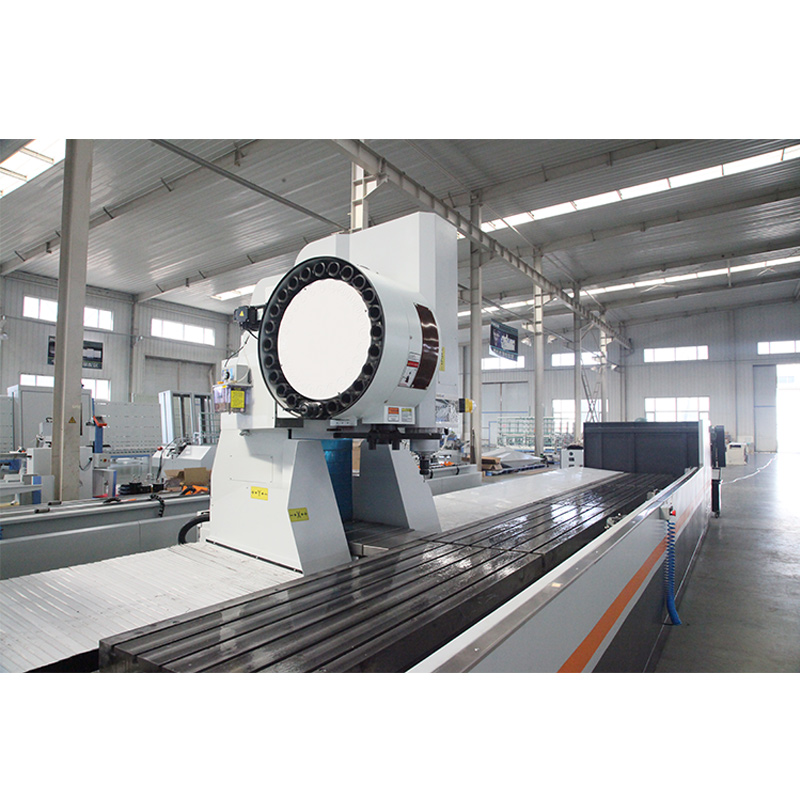

1.Automatic multiple machining center with functions of milling, drilling, tapping, routing, chamfering, designed for various length of aluminum, copper, profile steel,etc.

2.It adopts automatically chip removing machines.

3.The machines is equipped with BT40 spindle, which provides high connection rigidity.

4.The machine is equipped with protective cover, which guarantees the operating safety and cleanness.

5.The machine adopts arm-type tool magazine.

6.The machine can be customized into different models according to clients’ requirement.

TECHNICAL DATA.

STROKE

(Stroke for X axis) 4500/6000mm(2500mm~12500mm)

(Stroke for Y axis) 500/600mm

(Stroke for Z axis) 500mm

SPINDLE

(Spindle Speed) 12000 RPM

(Spindle Taper) BT40

TOOLS

(Capacity Of Tools Magazine) 24

(Tool Change Time) (2.0 sec)

MOVING SPEED

(X Axis Moving Speed) 60m/min

(Y Axis Moving Speed) 30m/min

(Z Axis Moving Speed) 30m/min

(X/Y/Z Feeding Speed) 1-1500mm/min

POWER OF MOTOR

(Spindle Driven Motor) 7.5 kw

(X/Y/Z Driven Motor) 3.0 kw

LUBRICATING SYSTEM

(Cooling System)(Water Cooling System)

PRECISION

(Position Precision Of X Axis) ±0.05 mm

(Position Precision Of Y /Z Axis) ±0.02 mm

(Repeating Position) ±0.02 mm

SIXE OF MACHINE

(Power Supply) AC 380V 50Hz

(Power) 20KW

(Air Pressure) 0.5MPa – 0.8MPa

(Height) 2600 mm

(Weight) 5000 kg~22000KG

(Area) 9300mm×2600mm×2700mm

MAIN COMPONENT CONFIGURATION

(Operation System) FANUC 0I MF SYSTEM

(Serve Motor) FANUC β

(Spindle Motor) FANUC,7.5KW, 12000 RPM

(Spindle)BT40, 12000RPM

(Tools Magazine) (HAND WHEEL INDUSTRY)24 TURRET

(Guide Rails) THK

(Bearings) NSK

(Ball Screw) TBI C5

(Electrical Parts) Schneider